Installation process of Perforated Wooden Acoustic Panel

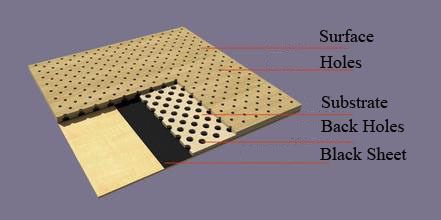

The Perforated Wooden Acoustic Panel adopts high-quality sheet material, which has the properties of environmental protection, fire resistance, water resistance. The decorative color set has a wide choice of materials, which can well meet the diverse acoustic and decorative needs of customers. Compared with wood grooved acoustic panels, they are relatively resistant to impact. The highest fire performance is A2, and the highest environmental performance is E1. The sound absorption effect of the product is good, combined with the use of silent sponge, it can effectively improve the indoor reverberation time and effectively improve the environmental clarity and fullness of speech.

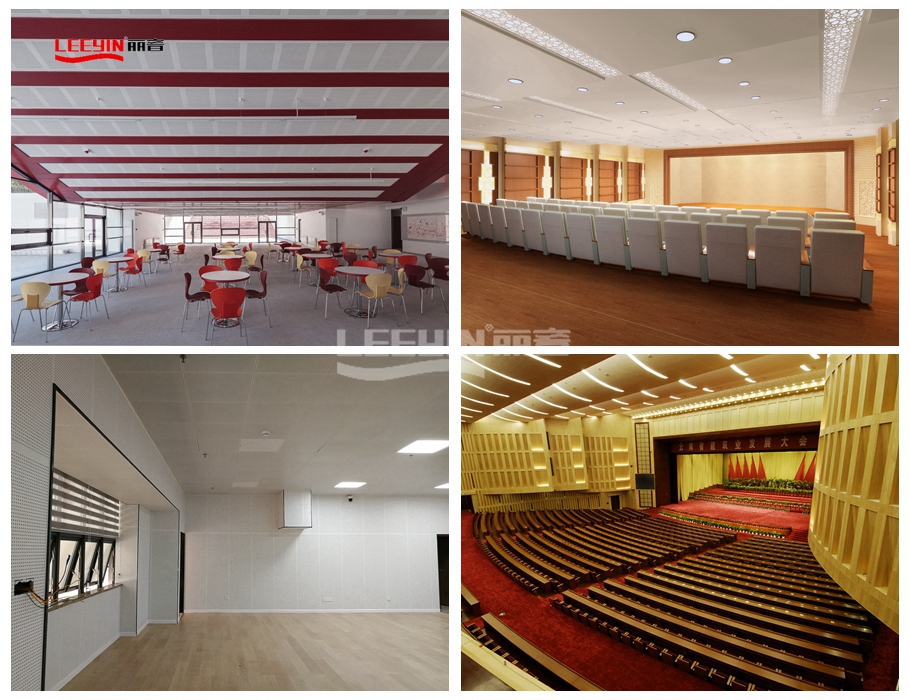

Scope of application: Multi-function Hall, Conference Room, Cinema, Auditorium, Hotel, etc.

Installation process:

Ⅰinstallation method:

(I) Preparations and environmental requirements before installation:

1. The installation site must be dry and the minimum temperature should not be lower than 10 degrees Celsius

2. The maximum humidity change value after installation at the installation site should be controlled within the range of 40% ~ 60%

3. The installation site should reach the above humidity standard at least 24h before installation

4. The Wooden Perforated Acoustic Panel must be left at the installation place for 48 hours, so that the Perforated Acoustic Panel can adapt to the indoor environment and be shaped

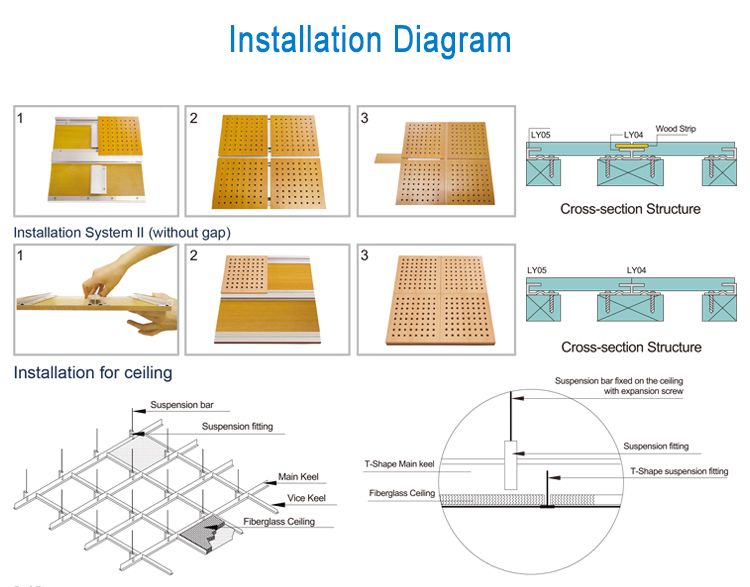

5. The wall surface to be covered by the Perforated Acoustic Panel must be installed with keels according to the design or construction drawings. The keel arrangement rule must be the same as that of the Wooden Perforated Acoustic Panel with a distance of 300 ~ 600mm

6. The distance between the base layer and surface of the keel is generally 50mm according to the specific requirements, and the plane flatness and vertical error are not greater than 0.5mm

7. If the keel gap needs to be filled, it must be installed first according to the design requirements to ensure that it does not affect the Perforated Acoustic Panel installation.

(Ⅱ) installation

1.Measure the dimensions of the wall, confirm the installation position, determine the horizontal and vertical lines, and determine the cut-out size for objects such as wires and pipes.

2.Calculate and cut some Perforated Acoustic Panel according to the actual size of the construction site (the opposite side is required to be symmetrical, especially pay attention to cutting the size of some acoustic panels to ensure that the symmetry on both sides) and lines (retractable edge lines, outer corner lines, connecting lines ), and cut it out for wire sockets, pipes and other objects.

Install the keel: Fix the wood keel / light steel keel to the building wall with nails. The nails must be more than 2/3 embedded in the wood keel / light steel keel. The nails must be evenly arranged and require a certain density. LY04 The keel is locked to the keel with screws.

Ⅱ Install the Perforated Acoustic Panel:

(1)The sequence of Perforated Acoustic Panel follows the principle of left to right and top to bottom

(2)The notch of the acoustic panel is advanced along the LY04 keel to the appropriate installation position

(3)If some solid wood acoustic panels have requirements on the pattern, each façade is installed in order from small to large according to the pre-programmed numbers on the sound-absorbing panels. (The numbers of acoustic panels follow from left to right, from bottom to top, and numbers from small to large )

Leeyin Perforated Acoustic Panel:

Copyright © Guangdong Liyin Acoustics Technology Co., Ltd. All Rights Reserved Sitemap Powered by